Implementation of Supply Chain Management: Step-by-Step Guide for 2025

15 Apr 2025

13 Min

140 Views

Implementation of supply chain management systems in the business impacts everything from inventory management to delivery. Such systems optimize transportation, visibility, and traceability, reduce costs, and boost customer service.

We at Cleveroad have more than 13 years of experience in supply chain technology. Based on our expertise, in this article, we will describe how a supply chain management system increases profit, speeds up delivery, and automates routine tasks. We’ll discuss how to implement supply chain management system and how it will help you adapt when your business expands, enters new markets, or cope with unexpected disruptions.

Key takeaways:

- Supply chain management systems streamline the flow of operations, helping consolidate shipments, reduce empty miles, and minimize handling errors

- Supply chain management implementation contains essential steps that cover the identification of the resources, reliable vendor selection, and more

- Supply chain management system implementation also consumes challenges that you need to solve to get all of the benefits and stay ahead of the competitors

What Is a Supply Chain Management System?

The supply chain management (SCM) system is a comprehensive solution designed to plan, monitor, and optimize all stages of the supply chain — from procurement and production to inventory management, logistics, and delivery. SCM consumes an integrated approach to managing the entire flow of processes and information about raw materials, products, and services at the enterprise. Supply chain management implementation helps businesses choose the best routes and methods of delivery, keep track of stock levels, monitor shipments in real-time, and prevent delays or disruptions.

Due to its clear process, SCM is in demand in various domains. So, let’s check how supply chain software works and what industries implement it.

Due to its clear process, SCM is in demand in various domains. So, let’s check how supply chain software works and what industries implement it.

How supply chain software work

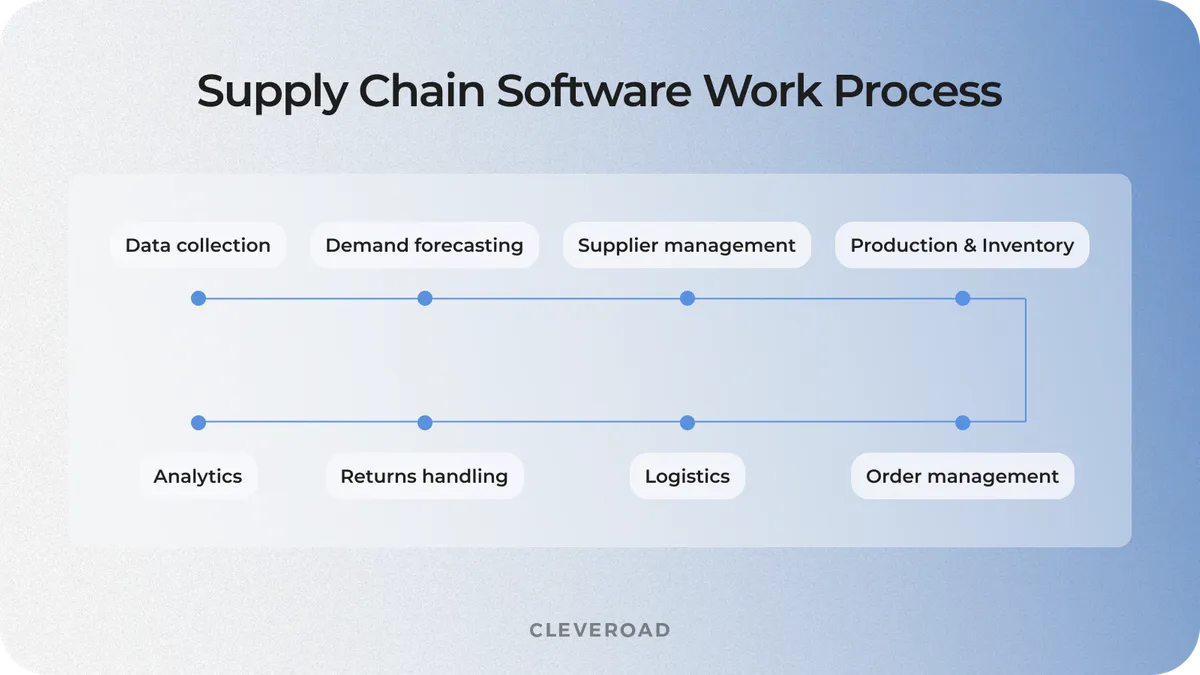

The supply chain software is a tool that supports and automates SCM. To understand how it operates and what it does, we should start by defining the stages of its work process.

Supply chain software work process

Everything becomes clear with a good example. Let’s imagine an online retailer that sells electronics, such as smartphones, laptops, and other gadgets. In such business, supply chain software will go through these eight stages:

Data collection. The system collects data from customer orders, supplier inventories, warehouse stock levels, and shipping partners.

Demand forecasting. The software analyzes trends (like back-to-school season or holiday sales) and predicts increased demand for laptops and accessories.

Supplier management. Based on the forecast, the system automatically places orders with suppliers for more stock, selecting the best delivery vendor and reliable quality.

Production & Inventory. SCM updates inventory levels in real-time as new stock arrives. The system allocates products to regional warehouses closest to target markets.

Order management. When a customer orders, the software immediately identifies the nearest warehouse with available stock and processes the order.

Delivery. The system selects the fastest and most cost-effective shipping method. It tracks the package all the way to the customer, providing live updates.

Returns handling. If the customer wants to return a product, the system creates the return label, refund process, and restocks returned goods.

Analytics. After the delivery, the system analyzes delivery times, customer and stakeholder satisfaction, and, if it was, return reasons.

What industries implement supply chain management systems?

The scope of the industries that can benefit from successful supply chain management system implementation is extremely diverse. Let’s take a closer look at the main of them:

- Logistics. SCM gives clear visibility into shipments and routes, lets you streamline route planning, and provides accurate delivery times.

- Retail. Supply chain management controls stock and tracks shipments. With SCM, you can automate order management and reduce errors to improve customer experience.

- Healthcare. SCM system helps track equipment and drugs in real time to provide patients with a required medical item when they need it.

- Automotive. A supply chain management system will help avoid delays in complex supply chains with thousands of parts and just-in-time production.

- Fashion. SCM systems let launch new collections faster, speed up delivery from factories to stores, and minimize delays.

Explore our logistics software development services to learn how we can help optimize your supply chains to minimize costs and boost customer satisfaction

Top-6 Benefits of Digital Supply Chain Management Implementation

If you’re looking at supply chain management implementation, you’re not just upgrading software — you’re setting your business up for real, everyday wins. Here’s exactly what you get when you implement supply chain management system solutions.

Enhanced supply chain visibility

Improved supply chain visibility is a vital advantage when you need to provide your customers with a better experience than your competitors do. According to Contimod, companies utilizing advanced visibility tools have experienced a 20% reduction in delays. It's not the guesswork anymore about locating shipments or having to wait for supplier updates – the SCM shows where it is accuracy.

Optimized inventory management

The implementation of supply chain management systems helps you manage stock and procurement. SCM lets you use solid data to know exactly what to order and when. Simple tools like automated reorder points save time and money. According to Vogue Business, luxury fashion retailers investing in smart warehousing technologies have enhanced their supply chain operations, improved efficiency, and reduced waste through real-time inventory data and decision-making processes.

If you need a separate inventory management software solution, check out our guide

Reduced supply chain costs

Good supply chain management implementation will reduce operation expenses. According to McKinsey & Company, companies cut supply chain costs by up to 10% and reduce inventory by as much as 25%. You will tighten purchasing, storage, and delivery, but you will not compromise on quality. Post-implementation of the software, SCM data helps you identify cheaper highways and better suppliers. Cut down on fuel, save on storage, and see the improvement of your bottom line.

Enhanced customer service

Speed and reliability of the delivery assure the customer to return for more. Forbes reports that 88% of clients consider service more important than ever, which shows the critical role of support in customer retention. SCM tools speed up the entire process, from order placement to delivery, earning customers' trust and thus consequently gaining you returning business.

Data-driven insights and decision-making

Good decisions come from good data. Supply chain management software implementation pulls together insights from across your operation. You will follow trends and predict demand easily with a confident renegotiation of contracts. A Gartner report indicates that data analytics and AI-powered insights will support 75% of all executive decisions by 2028, which underscores the integration of data in leadership roles.

Reduced risks and errors

Manual processes are prone to errors. Therefore, in implementing the supply chain management system, actions like order management and inventory updates are being automated to eliminate mistakes that cause lots of losses. Set alerts for early detection of issues to enable swift action. When you implement the SCM tools the right way, you always have a resilient supply chain amid disruptions.

Core Supply Chain Management Implementation Steps

Effective supply chain management implementation requires a complex process covering various steps, starting with identifying the current and future needs and ending with testing. Now, we discuss steps to implement SCM in your business:

Step 1. Identify your supply chain needs

Everything should start with defining the problems SCM needs to solve. So, check your current operations. Highlight where delays usually happen, where you need more visibility, and where coordination breaks down. Look at inventory management, supplier performance, and logistics workflows and identify what slows you down and what causes unnecessary costs. A clear understanding of these gaps gives the right approach for your SCM implementation.

Step 2. Decide on the SCM development option

Decide between a ready-made supply chain management software implementation and a custom solution. If your supply chain processes are simple, ready-made can speed things up with lower costs to implement. However, for businesses with complex logistics, a custom system built with your vendor’s expertise gives you better long-term value. Also, if you want to scale your business in the future, custom SCM is a more appropriate way because of its flexibility.

Step 3. Find a reliable supply chain implementation partner

Vendor selection is one of the most critical choices in the whole supply chain management process. Choose an SCM implementation partner with solid experience in logistics software development and integration. Check their portfolio and see if they have projects similar to yours. Review their case studies to understand how they solve challenges and deliver results.

Also, pay attention to how they communicate during initial discussions. A good vendor explains their process clearly, understands your business objectives, and shows a proven ability to deliver on time and within the supply chain budget. Don’t skip client testimonials — verified reviews on platforms like Clutch give you an honest view of your IT partner’s reliability.

We at Cleveroad have strong experience in developing and implementing complicated and multimodal systems. To show our expertise, we would like to present one of our recent case studies.

We provided end-to-end development services for our client from USA – Medical Device Consultants. They are a dynamic and expert company that plays an important role in the medical industry and helps medical device manufacturers confidently enter the U.S. and global markets.

We developed a document management system for medical devices manufacturers called QMS. The main goal of the project was to integrate the new QMS with the customer’s Quality control services, retaining all processes, functions, and roles needed for medical devices’ certification. As a result, our client received a successfully integrated system into the company's services, considering the whole business context, workflow, and compatibility with FDA 21 CFR 820 and 21 CFR 11 and the ISO 13485 requirements.

Here is what Breanne Butler, Client Liaison Officer at Prime Path Medtech™, have said about cooperation with Cleveroad:

Breanne Butler, Client Liaison Officer at Prime Path Medtech™

Step 4. Develop and implement your SCM system

After the selection of a reliable vendor, move into development and implementation. Your vendor should lead the charge on data migration, system integrations, and supply chain automation setups. Stay connected throughout this phase to solve challenges fast and make changes in time along the way. IT development partner collaboration provides your SCM implementation to move forward efficiently and make sure that each part fits your business.

Step 5. Train your staff

Training your staff is more important than it seems. When your team uses the new tools confidently, you maximize the benefits of your supply chain management system implementation. Work with your vendor to create clear, practical training sessions tailored to your team’s daily tasks. Vendors know the system inside out and can show your staff how to get the most out of it from day one.

Step 6. Test SCM and collect feedback

Before full launch, run your system in real-world conditions. Your vendor will guide tests and help you collect and analyze feedback from your team and supply partners. Use their expertise to define the problems early and fine-tune the setup. With this approach, you will implement a supply chain management system with fewer surprises and a smoother transition into full operation.

Challenges of Supply Chain Management Software Implementation

Despite the competitive advantages that you can get from implementing supply chain management system, there are also several challenges you should prepare for. You should consider the compliance risks, data accuracy and consistency, and more. Let’s take a closer look at the challenges that come with supply chain management software implementation and ways to solve them.

Integration with existing systems

Unquality integration of new software with your current stack during supply chain management implementation will bring a lot of problems. Data flow between inventory, orders, and delivery schedules needs to stay seamless to avoid delays. To realize it, work closely with your vendor to align integrations upfront using APIs and middleware to connect systems reliably.

We at Cleveroad smoothly implement SCM software with other business systems, including:

- Warehouse Management System (WMS)

- Transportation Management System (TMS)

- Enterprise Resource Planning software (ERP)

- Customer Relationship Management (CRM)

- Accounting and invoicing systems

- Inventory management tools

- E-commerce platforms

- Order management software

Such integrations empower the scope of your broader business opportunities and give advantages over the competitors.

If you don't know what software, WMS or ERP system, is best to enhance your SCM, read our detailed comparison to make your choice

Data accuracy and consistency

Inaccurate or inconsistent data badly influence every part of your entire supply chain management system implementation. According to the Emerald study, errors in inventory levels, shipment tracking, or supplier records lead to wrong decisions and customer dissatisfaction. So, your IT development partner must audit your data before you implement supply chain management system. Also, they should standardize formats across all platforms and automate data validation where it is possible. These steps keep your data clean and dependable from the start.

Cost overruns and budget constraints

Without tight control, supply chain management software implementation costs can quickly increase. Customizations, delays, or integration issues drive unexpected costs. Define your scope clearly with your vendor from day one. Also, build a detailed project roadmap and include a reserve fund for surprising issues. This approach keeps your budget in check while you implement supply chain management system successfully.

Explore top-10 strategies to reduce software development costs in our in-depth guide

Scalability and performance

As your business grows, your system must handle a larger amount of orders, suppliers, and real-time updates. Poor scalability restricts your future growth and leads to additional expenses. When planning how to implement supply chain management system, choose solutions built for scale. For example, we at Cleveroad provide cloud application development services with a flexible architecture that allows you to add more features and strategy modules as your needs evolve. Moreover, remember to test system performance under heavy loads early to avoid bottlenecks later.

Cybersecurity and compliance risks

Supply chains operate with sensitive data, from supplier contracts to customer delivery details. Weak security exposes your business to breaches and non-compliance fines. Focus on best practices for supply chain safeguards: encrypt data, control user access, and run regular security audits. Stay compliant with standards like ISO and regulations like GDPR for customer data protection.

Cleveroad specialists develop SCM software in strict adherence to various industry standards and regulations, such as GDPR, SOX, KYC, ERC-20, ERC-721, ST-20, AML, PCI DSS, PSD2, and more. Also, as an ISO-certified company, we implement ISO 9001 quality management systems and ISO 27001 security standards.

Cleveroad specialists develop SCM software in strict adherence to various industry standards and regulations, such as GDPR, SOX, KYC, ERC-20, ERC-721, ST-20, AML, PCI DSS, PSD2, and more. Also, as an ISO-certified company, we implement ISO 9001 quality management systems and ISO 27001 security standards.

How Cleveroad Can Help You Implement Supply Chain Management System

Cleveroad is a skilled logistics software development partner headquartered in Estonia, Central and Eastern Europian region. We offer various logistic services, such as custom software development, software reengineering, third-party integrations, digitalization, automation, and more, that cover all sides of industry processes and optimize your business.

For over 13 years, we’ve been helping logistics startups, SMBs, and enterprises accomplish their goals and improve their product performance. The scope of solutions we provide is large and includes warehouse tech, Transportation Management Systems (TMS), last-mile delivery solutions, Enterprise Resource Planning (ERP), and more, by which we help our clients track their packages to increase customer satisfaction.

Choosing Cleveroad for supply chain management implementation, you’ll get:

- Deep experience in implementing 3-rd party integrations for logistics, such as Google Maps, Shippo, Quickbooks, Upkeep, SAP ERP, Hubspot, etc.

- Free Solution Workshop stage to align your supply chain management needs with technical implementation

- Partnership with an ISO-certified company implementing ISO 9001 quality management systems and ISO 27001 security standards

- All guarantees for your business information security and signing NDA per your request

- A high level of expertise in providing cloud services is proven by receiving Amazon Web Services (AWS) Select Tier Partner status within the AWS Partner Network (APN)

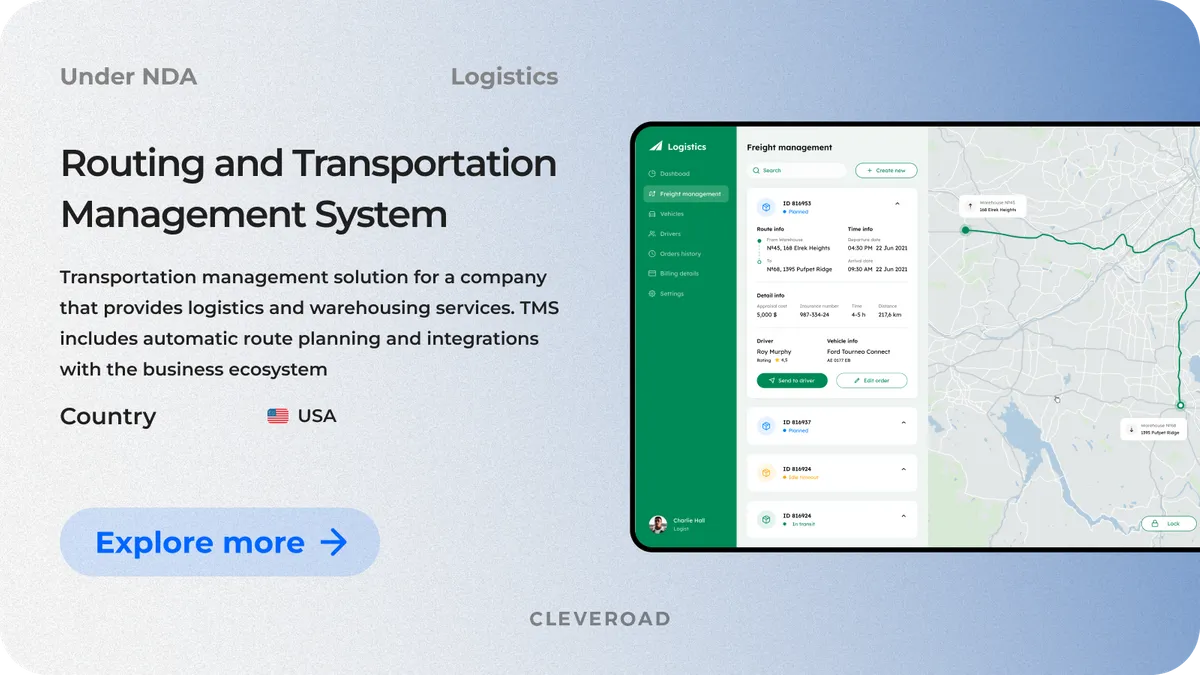

We’re experienced in developing complex supply chain management solutions. Let us show you our case - a route-planning Transport Management System.

Our client from the USA provides warehousing and long-distance cargo delivery and has a separate branch of last-mile delivery service for marketplaces of various sizes. The company needed a reliable logistics software development partner to create transportation management and automated route planning software integration in already existing business systems.

Cleveroad team developed a flexible and highly customized transport management system covering of all processes, including the cargo transportation settings, employees’ workflows, fleet control, and the Last Mile Delivery service. The solution also includes automated route planning with manual adjusting options and control modules. Moreover, we built a drivers’ mobile app to navigate through the custom routes.

As a result, the customer received a custom transportation management platform developed from scratch and integrated with the other business systems in use. TMS helped reduce the total delivery time and increased the return on each vehicle unit, increasing the gross profit. In addition, the system led to a total logistic overhead reduction – an indicator decreased by 27-36% due to automation, better control of vehicles, and route planning.

Implement a supply chain management system with domain experts

Get full-fledged SCM software development and implementation assistance from an expert IT team with 13+ years of experience in the Logistics domain

The supply chain management (SCM) strategy is a complex method to control each operation in your company. SCM consumes an integrated approach to managing the entire flow of goods and services, processes, and a source of information about raw materials, products, and services at the enterprise.

SCM will bring you a lot of benefits. Here’s exactly what you can do with implementing supply chain management system solutions:

- Enhance supply chain visibility

- Improve inventory management

- Reduce supply chain expenses

- Enhance customer service

- Get data-driven insights and decision-making

- Reduce risks and errors

There are six phases of supply chain management implementation:

- Step 1. Identify your supply chain needs

- Step 2. Decide on the SCM development option

- Step 3. Find a reliable supply chain implementation partner

- Step 4. Develop and implement your SCM system

- Step 5. Train your staff

- Step 6. Test SCM and collect feedback

SCM implementation involves these challenges:

- Integration with existing systems

- Data accuracy and consistency

- Cost overruns and budget constraints

- Scalability and performance

- Cybersecurity and compliance risks

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article