Truck Load Planning Software: Essentials, Benefits, and Features

Updated 07 Mar 2025

17 Min

1742 Views

Load planning software is an indispensable tool to effectively coordinate the safe and efficient loading and unloading of goods. Implementing modern technologies such as load optimizing software can meet these challenges, ensuring optimal resource utilization and increased efficiency.

As an IT provider with 13+ years of experience in logistics software development, we are here to share our expertise with you and explore how to build load plan software to help logistics and transportation companies enhance the efficiency of their operations.

What is Load Planning Software, and Why Business Needs It?

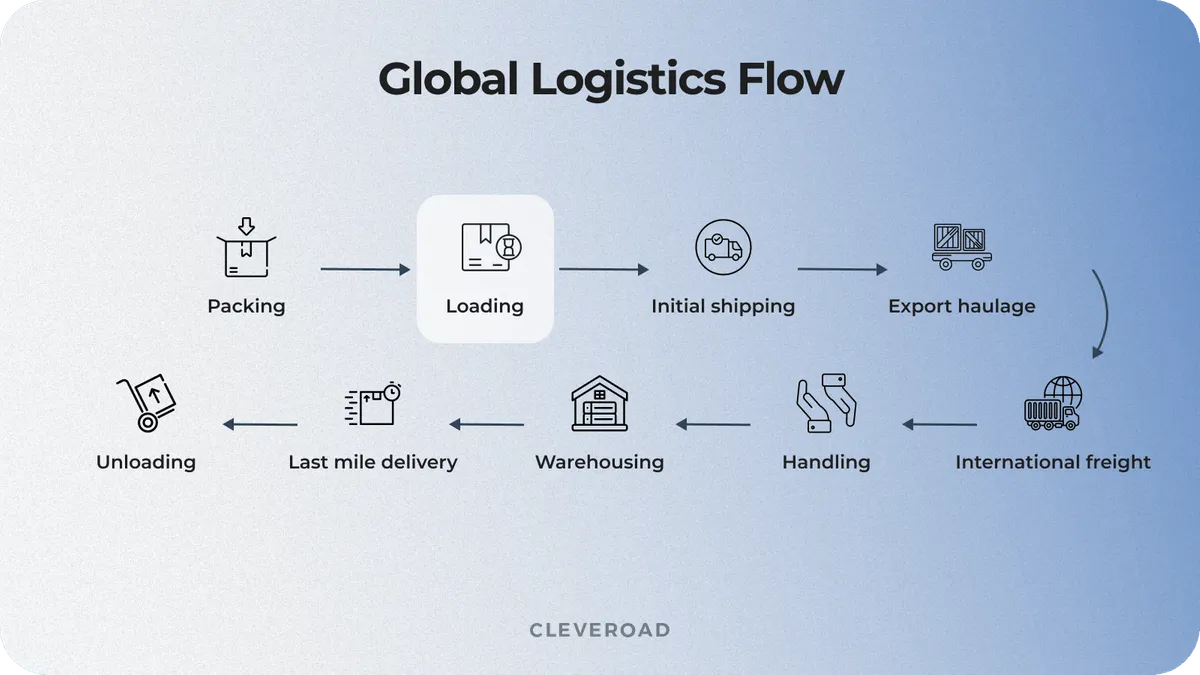

Load planning, also called load optimization, implies the process of consolidating shipment to use the power of trucks, railcars, pallets, and any other kinds of containers in the most effective manner. The main goal is to cut down transportation costs by reducing the number of vehicles on the road. Moreover, optimizing loading prevents cargo damage, saves loading and unloading time, and boosts clients' satisfaction resulting in higher customer loyalty.

When deciding to build a load planning software, you should also consider container and trailer types and make it possible to switch between them easily. You might not utilize all kinds of containers to ship your items, so concentrate on the ones that you need.

Containers can be divided depending on the mode of transportation and products types:

- Standard maritime containers (e.g., general-purpose, flat rack containers, open-top containers, etc.)

- Railroad transportation containers (e.g., high cube containers)

- Air freight containers are also called Unit Load Devices

- Shipping containers (e.g., dry van, step deck, flatbed, etc.)

With so many options available, it’s pretty challenging to load the maximum number of orders into a single container. There are a lot of factors that need to be considered, such as a vehicle's specifications (refrigeration, for instance), loading sequence, destinations, type of cargo, and much more.

In addition to that, a manual approach is a tedious task, leading to substantial operational overhead. Plus, your embarkation specialists’ job can be complicated by the number of items increased in the vehicle or container, primarily if they deal with odd-shaped objects. That's why you need load optimization software to take the inefficiency out of the cargo planning.

The load planning software can help your business do more optimal planning flow, lowering the transportation cost and reducing the carbon footprint by simply needing fewer truckloads. This technology solution automatically creates a loading plan for your route, evaluates and streamlines each pallet during the pick, pack, and ship processes. Then, after optimizing your routes, the system ensures an effective loading process into your trucks.

Load planning in supply chain

What businesses can benefit from truck loading software

Load planning software is a tool that plays a key role in optimizing loading and distribution processes. With its help, companies can efficiently use the space of transport units, minimize costs, and ensure safe delivery of goods. Among the companies that need cargo load planning software are:

Logistics companies

To optimize route planning and increase the efficiency of cargo transportation for all destinations.

Warehouses

To boost the distribution and loading of goods in warehouses, minimize wasted space, and improve shipment efficiency.

Transportation companies

To increase utilization of transportation units, reduce delivery time and costs, and ensure cargo security.

Manufacturers

To enhance logistics processes, reduce shipping costs, and ensure on-time delivery of products to customers.

Retailers and distributors

To efficiently organize the delivery of goods to stores or customers, manage inventory, and minimize logistics costs.

Load planning solution benefits for logistics businesses

Robust load planning is crucial for reducing costs, improving delivery speed, and ensuring compliance. AI-driven solutions optimize cargo distribution, enhancing profitability and sustainability. Let's find out other crucial benefits of using this logistics software for cargo loading.

Cost savings and higher profitability

AI-powered freight loading software slashes fuel expenses, driver costs, and empty miles — maximizing margins while keeping pricing competitive without sacrificing service quality.

Optimized space and sustainability

Smart algorithms make the most of cargo space, reducing emissions, cutting logistics costs, and ensuring Environmental, Social and Governance (ESG) compliance by minimizing unnecessary trips.

Faster and smarter planning

AI automation eliminates manual errors, optimizing load distribution within seconds and quickly adapting to shifting demand for seamless operations.

Superior customer experience

Integrated with TMS, WMS, and ERP systems, AI ensures precise, on-time deliveries, improving SLA compliance and minimizing fulfillment errors.

Enhanced safety and compliance

Intelligent load balancing prevents overloading, mitigates transit risks, ensures legal compliance, and reduces damage during transport.

Seamless integration and real-time insights

Cloud-based solutions leverage IoT, GPS, and AI analytics, delivering real-time data for smarter decision-making and optimized fleet performance.

Now, we’ll discuss more about the types and functions of container load planning software for you to make a proper decision on what to develop for your business.

Discover more about how you can benefit from load software development with our freight management system development services!

Load Planner Software: Types and Options

Forming optimal cargo is crucial for different logistics industry players, especially those who deal with loading multiple goods. Thus, let’s take a quick look at two main truck load planner approaches.

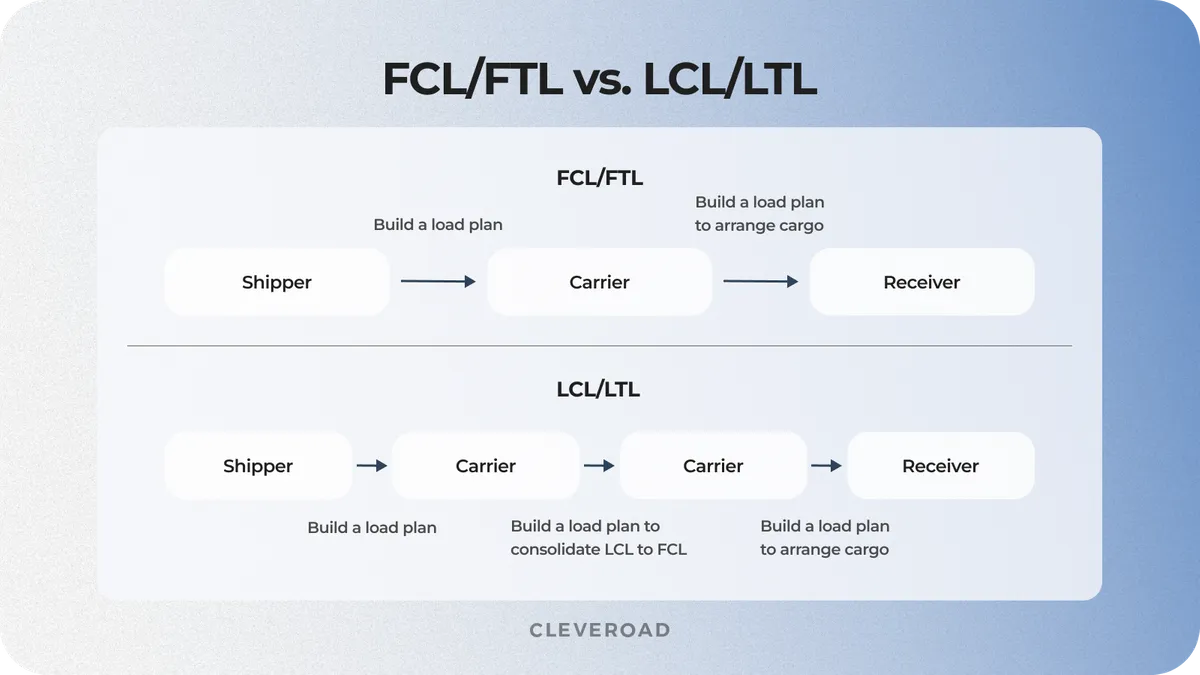

FCL/FTL shipping

Full container loads (FCL) or full truckloads (FTL) shipping is cheaper than partial loads shipments (in price per unit or cubic meter comparison) and easier as it requires fewer arbitrators. These types of shipments imply that shippers (manufacturers and retailers) stuff the shipping containers themselves and turn them over to the carrier to deliver to the last destination.

The challenge arises if such freight consists of diversified items. In this case, shippers and carriers that move mixed cargo and/or manage different kinds of packaging have to define how to stack their freight in the trailer in the best possible way. This is where it’s better to consider consolidated shipments using cargo loading software.

LCL/LTL shipping

Less-than-truckload (LTL) and less-than-container load (LCL) transportations engage freight consolidation to reduce shipping costs. That implies carriers, 3PL (third-party logistics partners), and freight forwarding organizations that deal with numerous shippers have to combine cargo and arrange it in the truck considering different restrictions like balance, fragility, stackability, etc.

So, if you appeal to a transportation company to move, for example, auto spare parts, it will be LTL shipping, and the carrier will mix your goods with other freight. After that, the consolidator gathers such LCL loads from all shippers and uses a container load planner to group them into FCLs. Then, when the cargo is delivered to the destination port, it is deconsolidated and dispatched by truck right to the end customer's adress.

The difference between FCL and FTL shipping and LCL and LTL shipping

The problem is that load plan software development is complicated and error-prone if made by hand. So, applying specialized software can enhance the load planning process, save time, and gain the load calculations accuracy. But, the keystone of implementing load planning software in cooperation with a reliable technical company with confirmed expertise in Logistics software development services.

What Features Should Be Included in the Load Planning System?

It’s time to consider the functionality needed to build load optimization software. We’ve put together core (MVP) and advanced features to make this section more useful for you.

MVP features to build load planning system

The main idea behind the core (MVP) feature set is to create a truck load platform with enough functionality to satisfy basic business needs, considering all the security matters. MVP development service will allow you to get a working product without investing a lot of money in creating a full-fledged software solution. After you ensure product viability, you can add more sophisticated features.

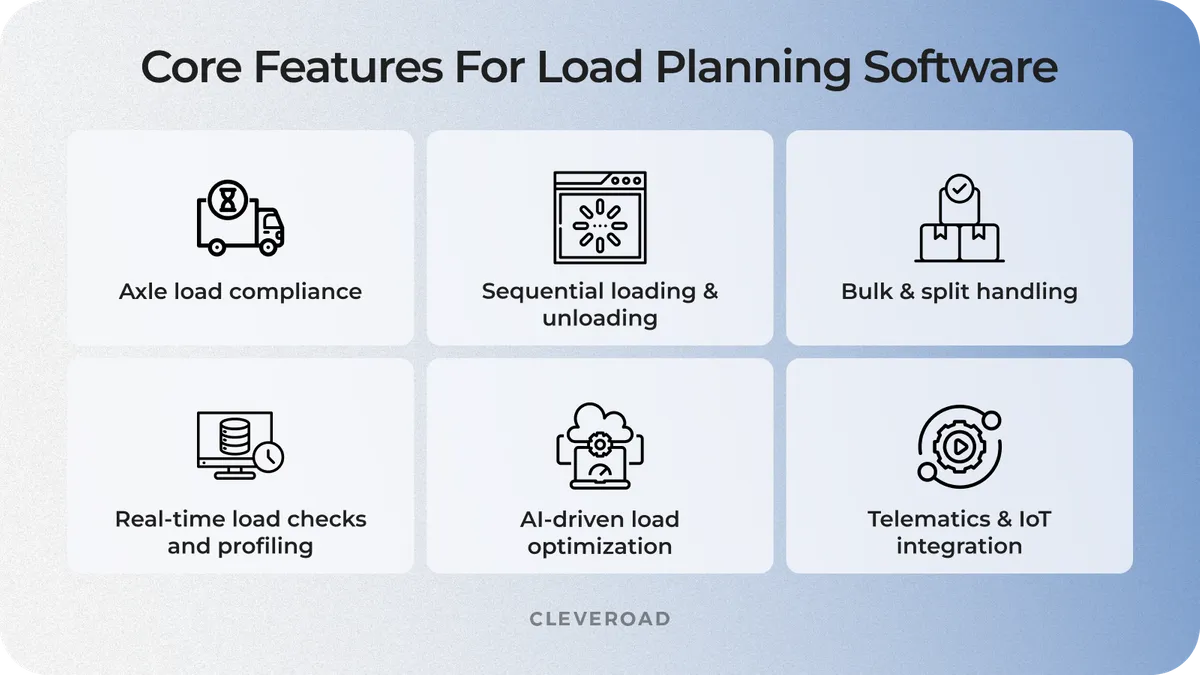

Key load planning system features

Axle compliance and load stability

These features enable proper weight distribution across axles and optimize double-stacking positions for maximizing trailer utilization while remaining compliant with regulations. They automatically boost loading strategies according to weight limits and truck-trailer configurations to avert fines.

Pick and unload in sequences

This functionality optimizes the picking order in warehouses to reduce travel time and ensures the pack cycle fits with goods needing to be loaded in sequence with the stop. Providing a multi-dimensional, three-dimensional view of the cargo and truck cargo-container volume and weight streamlines unloading and eliminates unnecessary cargo handling at delivery points, enabling the person responsible for loading to work efficiently.

Bulk and split item handling

It determines if products should be loaded in bulk for efficiency, however, groups products that should go together in one delivery instead of splitting them across multiple pallets. This enhances warehouse processing and enables pallet load operations to be tuned for easier handling and transport.

Real-time load validation

It delivers real-time insights while loading, verifying weight compliance, axle balance, and trailer space limitations. This eliminates misloading errors or regulatory compliance problems and eliminates manual recalculating. It has also integrated 3D load visualization, allowing for the correct placement of the load.

AI-powered load optimization

This feature generates the most space-saving and cost-fueling load planning and optimization algorithms using machine learning and historical shipment data. By dynamically responding to different types of cargo constraints, it eliminates empty space and optimizes routes per load.

Integration with telematics and IoT

You can integrate your load planning software with telematics and IoT sensors to track cargo conditions, vehicle status, and load integrity in real time. It significantly improves supply chain visibility and allows for both planning and optimization in real time. The system also makes it easier for forwarders to manage their fleets by dynamically altering routes and load capacities.

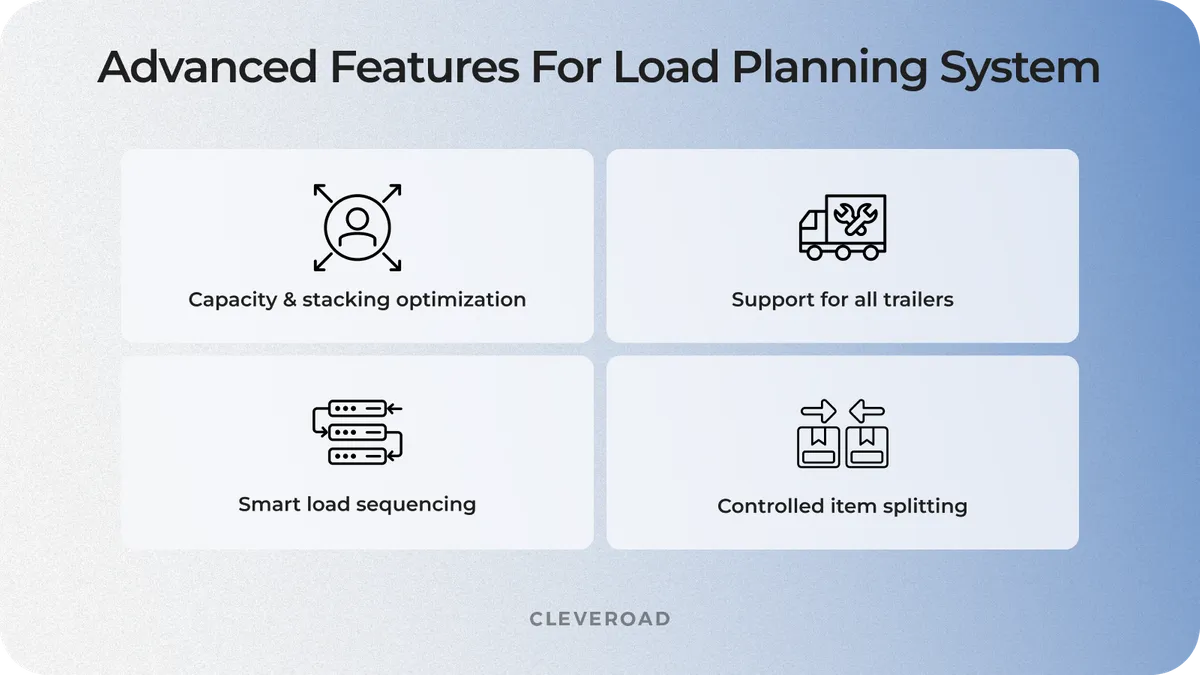

Advanced functionality for load planning system

Such advanced truck and container loading software also utilizes advanced features to optimize not only stacking but also weight distribution as much as possible to improve efficiency and precision.

Here are several of those features that help you make the most of trailer capacity, enhance sequencing, and ensure compliance with customer and regulatory requirements.

Advanced features to implement in load planning software

Advanced capacity and stacking optimization

These features also automatically double-stack, and select quick-max capacity to utilize each trailer step. Due to them, the cargo loading software recognizes whether the load will fit in a certain area and adjusts the way it gets stacked. It also enables logistics managers to accelerate cargo density optimization while meeting safety and regulatory requirements.

Unlimited trailer types

This is critical to enable multimodal logistics if to support multiple types of trailer and loading containers. The users can input different equipment specifications based on axle capacity, compartment, pinwheel configuration, and door locations. The flexibility allows for a seamless connection between the different classes of transport, maximizing competence in specific transport and minimizing changeover cost.

Flexible load and unload sequencing

The software also optimizes the sequencing of stops, helping to position goods in the best way in the trailer so that they can be removed at each stop as slowly as possible. For both truck and container loading for shipment, arrangements are made to minimize unnecessary handling. It also includes customer-defined overrides for prioritized unloading and other business-specific needs.

Split item control

As a result of re-ordering pallets, the system controls which items are co-packed within the pallets to reduce travel time and ensure efficient fulfillment of orders. Integrated palletizing logic keeps items bound for the same location together unless absolutely necessary. This shortens sorting time at warehouses, minimizes errors during shipments, and increases accuracy across logistics.

How to Integrate the Truck Load Optimization Software With Your Workflow?

Load planning software development and implementation can be performed in many directions. We’ll describe the standard approach for logistics product creation, but the number of stages can differ depending on your business needs and requirements.

Step 1. Define the integration needs of load planning app

Firstly, you should understand your business goals and challenges before integrating truck loading software. Whether you’re looking to boost payload capabilities or optimize route planning, clear objectives will allow developers to deliver a customized solution. Review cargo-placement rules, including stacking, weight distribution, and order sequencing, to be as efficient as possible. By doing so, you will be able to efficiently optimize your loading process.

Step 2. Choose trustworthy IT partner

The load optimization software development will be better performed with a professional IT partner with deep expertise in the logistics domain. But how to find a reliable vendor? We’ll give you some hints of what to pay attention to while choosing a logistics software development partner.

- Analyze tech expertise in logistics. Look for software vendors with industry experience who specialize in developing logistics solutions.

- Examine customer reviews. Check reviews on platforms like Clutch or GoodFirms to gauge satisfaction and service quality.

- Familiarize yourself with the vendor’s portfolio. Review portfolios to see the technical vendor's ability to solve logistics challenges.

- Assess technical skills. Verify the IT company's competence in software development technologies and their application to logistics.

- Check the communication policies. Ensure the software vendor's team is willing to discuss project details openly and answer your questions regularly.

Step 3. Solution Workshop and Discovery Phase

Solution Design phase includes identifying and analysis of your business requirements and challenges to draft a high-level feature list and solution architecture for future cargo planning software. Considering your goals and constraints, the software vendor estimates project costs and proposes tailored solutions within about two weeks.

- Solution Design Phase is free of charge to align your business requirements with a proper tech implementation.

Following this step, the Discovery Phase services offered by the software vendor streamline project requirements into a comprehensive plan, expediting load plan software development. Your logistics software experts develop a detailed feature list, analyze business processes, and facilitate a quality attributes workshop. They create a design concept and UX map, provide cost estimates, conduct competitor analysis, and assemble a dedicated team to build your logistics solution. Upon agreement, they proceed to sign a development contract, ensuring transparent collaboration.

Step 4. Development and integration

You can choose between the two options of load planning and scheduling software development:

- Standalone solution development: Creating a unique load planning software product that fully meets your needs and objectives.

- Integration with existing systems (TMS): Align the new load plan solution with your current traffic management systems (TMS), ensuring they are interoperable and complementary.

Like any other IT solution, truck load planning software is typically developed during sprints, which are two-week intervals for certain functionality fulfillment and integration of various tools, e.g. trucking APIs. Each sprint starts with a planning session and ends with delivering a working product or feature. All teams are directed by PMI-certified project managers who can clearly communicate the requirements and coordinate workflow and communication between stakeholders and the team.

Combining different pieces of software into a single system will allow you to centralize and interconnect all your supply chain features and tools. This will improve workflow efficiency and prevent any disruption in the supply chain management system, ultimately reducing the freight cost of shipping.

Step 5. Support and maintenance

Cargo planning software solutions are complex interconnected systems that may require multi-tier technical support options and maintenance services. This work may include support for the deployed software, version upgrades, adding new functionality, code optimization, etc.

Consider complementing your load planning solution with freight management system to ensure the most accurate supply chain management

Best Practices for Effective Load Planning Software Development

Truck load planning software needs to be quick, flexible, and precise. To ensure this, the developers need to focus on usability, automation, and integration with the rest of the systems. Let’s discuss how to achieve this aim.

Advanced AI automation

Automation accelerates the load planning processes and minimizes errors. Moreover, it speeds up the load planning process and reduces the possibility of human intervention, speeding up decision making.

So, in order to create a load optimization software, able to quickly calculate how much to order, you should choose the suitable vehicle or container, and schedule shipments with the least amount of human input. That's why, smart algorithms have to offer up optimum routes and stacking methods so that wasted space is diminished. Moreover, the real-time data updates should allow logistics teams to make decisions without time lag.

In addition, with features such as real-time data updates, logistics teams will make informed decisions and have the speed as well as accuracy in their operations.

Ensure adaptability

The demands of logistics are ever-changing. Planning adapts to changing priorities, different types of cargo, and unanticipated delays. That’s why the software also has to ensure that load distribution changes with time, like how it packs a 20ft container or an air container.

For that, developers use modular architecture with microservices and API-based integration, enabling the system to easily adapt to multiple transport needs. Configurable rules enable logistics businesses like yours one to comply with industry-level standards. What is more, configurability in the cloud means these laws can easily be updated remotely to stay compliant with changing international regulations.

Smart load distribution

Data from smart algorithms makes efficient planning possible by optimizing available space in vehicles and weight. The software has to minimize container packing to reduce transportation costs. In order to optimize container usage, it should evaluate cargo dimensions, weight restrictions, and stacking measures. A good system will enable effective load planning by eliminating empty spaces and lowering freight charges.

Additionally, IoT sensors complement load optimization by delivering real-time information about the weight, size, and environmental conditions of the cargo. With weight sensors, dimension scanners, and tools for cargo positioning, the software can dynamically optimize stacking and placement for better space utilization.

There must be a balance between automation, adaptability, and optimization in order to create truck load planning software. A perfectly functioning system streamlines load processes, leading to lower costs and higher efficiency.

Reaching this balance is a must for creating efficient truck load planning software. However, you should note: even though there are a lot of ready-made solutions to choose from, not all are managed to cover your unique business needs. Moreover, off-the-shelf solutions are harder (in some cases, impossible) to integrate with the existing systems, while managing logistics solutions separately isn’t efficient.

So it’s better to focus on custom app development to get a scalable solution meeting your load planning logic. Making a personalized product means getting load planning software highly adaptable to your enterprise's business logic, its processes, and units.

Cleveroad — Your Reliable Partner in Load Planning Digitalization

Cleveroad is a logistics software development company from Estonia helping businesses create any-scale software solutions, including WMS, TMS, Load Planning Software, Freight Rate Management System, etc. With over 13+ years in software development, we have built up expertise in multiple domains, among which Logistics takes a leading position.

Our team has proven expertise in developing logistics solutions such as TMS, WMS, SCM, ERP, and other custom solutions that help transportation companies reduce operational costs, optimize inventory usage, decrease delivery time, and improve business efficiency. We start cooperation with in-depth business analysis to guarantee you concrete business values and high-quality outcomes.

By collaborating with us, you’ll receive a row of benefits such as:

- Practical experience in logistics software development: load planning software, warehouse management systems, transportation management systems, electronic resource planning, etc.

- Collaboration with an ISO-certified partner integrating ISO 27001 security management and ISO 9001 quality management standards

- Consultation on development and integration of your load planning solution with our logistics subject matter experts

- Full-cycle logistics software development services, including custom load planning system development, Discovery Phase, UI/UX design

- On-demand IT services: cloud logistics solutions development, legacy software modernization services, IT consulting, managed IT services, etc.

- Signing of non-disclosure agreements (NDAs) upon your request at the first contact

- Flexible cooperation models based on your needs: Staff Augmentation, Dedicated Development Team, Project-Based model

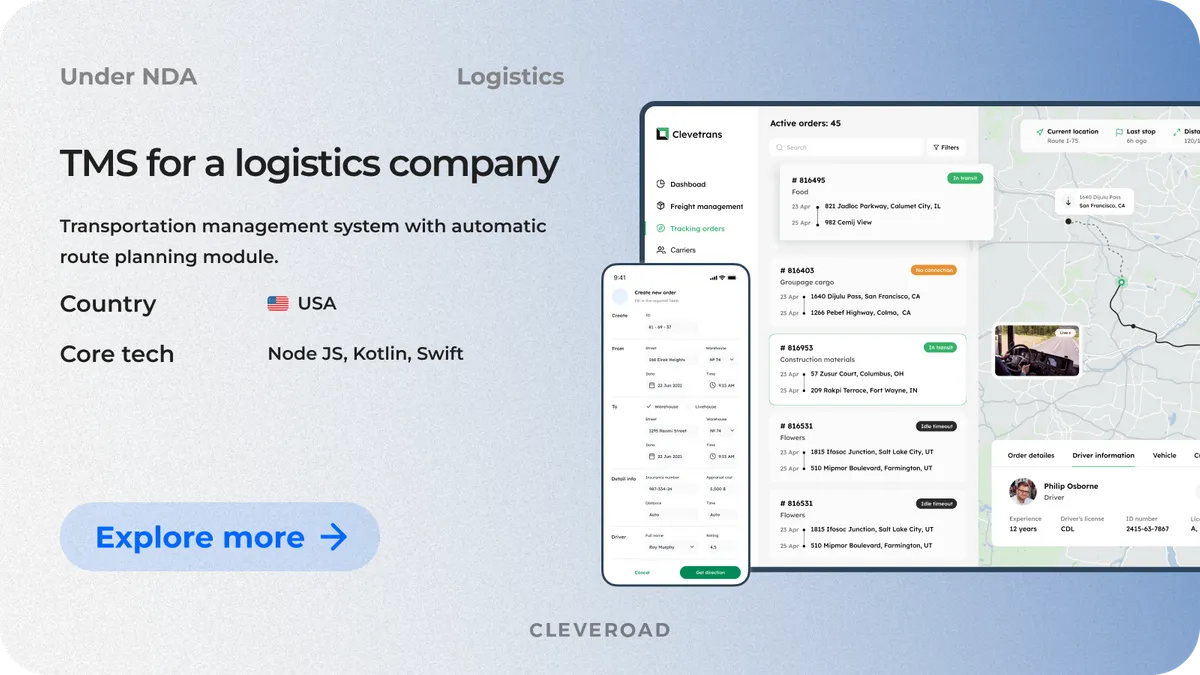

Recently, we’ve delivered one of the logistics management solutions, namely, transportation management system (TMS). The platform has a built-in automated route planning module to cut costs on planning, optimize fuel management, and create an organic and coordinated logistics ecosystem.

We’ve successfully delivered end-to-end TMS, including the following modules:

- A Fleet management module helps the company track and manage fleets. For example, fleet managers can create a group of vehicles utilized in transportation flow and modify it due to changing business processes.

- Delivery points management module allows TMS users to determine everyday work location and track data changes in real-time.

- An Access system for company staff enables access level management according to the employees’ role RBAC approach.

- “Jobs for delivery” module that allowed integration with existing WMS and CRM systems for smooth data transmission.

Logistics is a complex industry requiring a severe approach to implementing industry-specific software. Our team is prepared to help you architect a top-notch custom software solution for load planning and other parts of the supply chain. We’ll also take care of the entire software development life cycle: from the Discovery phase to maintenance for the long term. Let's cooperate and develop a powerful logistics solution in tune with your time, budget, and expectations.

Develop load optimization software with domain specialists

Get the robust load planning software solution for seamless logistics in your business, optimized efficiency, and smarter resource management

Load planning means allocating different items to a space in truck or container, while minimizing the overall movement of goods through that space. Businesses can harness planning techniques and an API to improve operational efficiency. This logistics process ensures that shipments are properly arranged, resulting in lower costs and a greater offer of resource utilization.

Load planning software is a specific tool that allows businesses to know the optimal way to organize and transport their products effectively. It uses intelligent loading algorithms to use space efficiently and minimize loading and unloading costs. The software handles order quantities, helps to load at the loading dock, and optimizes overall logistics efficiency.

Manual file loading, automation systems, and loading optimization software are a few options to boost container loading patterns. Sophisticated tools calculate the optimal method of arranging cargo so space is used efficiently, while minimizing time spent loading and unloading. Advanced software even can illustrate how much cargo fits a container before you will load it, making the progress as systematic and advanced as could be allowed.

Load planning entails the process of adding the load in such a manner as to optimize space and weight distribution. It has to also take into account loading and unloading processes to prevent unnecessary delays and disruptions to the process. Because of this, providing auto-filling visualization with advanced software determines the best configuration, making maximum utilization of the given resources and can fill you in on how much cargo could fit into the given restraints.

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article