Yard Management System: Concept, Principles, and Implementation Value

Updated 26 Nov 2024

15 Min

1807 Views

The Yard Management System (YMS) implementation is an efficient way to delve deeper into the Logistics domain. Moreover, it helps improve warehouse area safety, boost warehouse capacities, as well as optimizing loading and unloading operational costs, and minimize disruptions in delivery schedules and item shipments. However, it is full of specific peculiarities every entrepreneur should be aware of to make the YMS system profitable.

As an experienced IT provider with 12+ years of expertise in logistics software development, we will share our experience with the yard management system concept, benefits, core features of such solutions, their costs, and more.

What Is Yard Management System?

The Yard Management System (YMS) refers to a solution architected to track the movement of trucks in the enterprise yard and manage workflow in the distribution hub or warehouse. It connects transportation and storage, so this solution provides significant capabilities for higher control levels and productivity. Let’s explore yard management operation logic. The system allows you to create transport routes according to control points in the yard warehouse area. The RFID technology automatically identifies vehicles and checks the correctness of the route.

Let’s explore the yard management in logistics in detail.

What is yard management?

Yard management definition is a combination of scheduling, coordinating, and managing operations in a warehouse or distribution center, such as inbound and outbound trucks, containers and trailers, personnel, shipments, and others.

The goal of yard management processes is to optimize the flow of traffic and resources in and out of the yard, reduce expenses, and improve customer experience. It is vital to logistics and modern supply chain management, especially for manufacturing warehouses, allocation centers, and transportation hubs, such as railyards and ports.

How do yard management systems work?

A yard management system is multifunctional software allowing you to control and organize all the operations, equipment, vehicles, containers, and resources throughout the entire warehouse, distribution center, or manufacturing facility. YMS opportunities may be integrated into the warehouse management software (WMS) to fulfill the entity’s requirements and aims. Let’s see what logistics business processes can be automated and enhanced through an efficient yard management system:

- Delivery schedule. YMS minimizes disruptions in delivery schedules and product shipments.

- Queue management process. The system can create automation in the vehicle queuing in the loading and unloading area.

- Supplier management process. YMS automates calculating ratings for carriers and suppliers based on performance metrics.

- Cost calculation. YMS optimizes loading and unloading operations costs by reducing idle times and labor costs.

- Vehicle distribution. The software optimizes vehicle flow distribution near the warehouse and ensures an efficient process for loading and unloading goods.

- Status monitoring. The yard management system provides real-time visibility and notification for any issues or delays.

- Errors and issues handles. YMS can help you eliminate errors in vehicle placement near ramps and loading areas.

- Shipment time planning. The system allows for the automated monitoring of planned shipment times, ensuring that products are loaded and unloaded as scheduled.

Benefits of Yard Management Technology for Various Business Domains

The impact of YMS extends far beyond the confines of a single industry. Its versatility allows it to cater to many sectors, each with its challenges and requirements. We’ll embark on a journey through the diverse landscape of businesses that benefit from YMS implementation.

Retail

The yard management system can help you optimize the flow of goods in and out of retail distribution centers. It provides real-time visibility while reducing the need for manual labor in managing warehouse and yard operations. By integrating advanced tracking technologies like GPS and RFID, the system ensures accurate monitoring of vehicles, trailers, and inventory within the yard. It leads to faster dock assignment, reduced waiting times, and improved overall efficiency.

Logistics and freight companies

YMS organizes the movement of cargo trailers within yard inventory and distribution centers and optimizes supply chain efficiency in logistics and freight companies. By utilizing real-time data, YMS makes it possible for logistics companies to automatically generate delivery schedules. Even more than that, it enables the automation of yard operations, which helps eliminate the need for manual yard management and reduces labor and equipment costs, which makes this tool very essential in the contemporary logistics industry.

E-commerce

In the e-commerce domain, YMS ensures that order fulfillment is carried out efficiently. It helps streamline operations and enhance customer satisfaction. Yard management systems generate valuable data insights and analytics that e-commerce companies can use for strategic decision-making, giving them a competitive edge. In addition to that, better management of returns has also simplified the procedures for the customers as well as the enterprises.

Chemical

Looking at the existing transportation management systems in chemicals, which improve supply chain performance, it is obvious that the best yard management system will help automate compliance checks instead of manual processes, which makes it possible to process all operations with regulatory measures. It provides real-time visibility into chemical inventory and allows for better stock inventory management and operational efficiency. Additionally, YMS assists in optimizing routing and scheduling for chemical shipments, ensuring that hazardous materials are transported via the safest and most efficient routes.

Automotive companies

A yard management system minimizes storage costs and reduces excess inventory for automotive companies, streamlines yard activities and warehouse operations, cutting down labor and equipment costs tied to manual yard transportation management. Additionally, it generates valuable data and analytics, enabling automotive companies to optimize their operations further, making the entire process more efficient and cost-effective.

Agriculture

In agriculture, YMS offers to minimize the risk of spoilage during transit or storage, preserving product quality and reducing waste. It supports the efficient use of resources, including labor, equipment, and storage space. Moreover, it enhances customer satisfaction by ensuring that fresh produce reaches customers on time and in optimal condition.

Manufacturing

A yard management system provides optimized managing of the flow of materials within the warehouse in manufacturing. It ensures that materials are readily available for production. Furthermore, it helps reduce production downtime while providing real-time visibility into the status and location of materials within the yard and warehouse, enhancing efficiency and keeping production on schedule.

Basic Features of Yard Management System

You can build a YMS with any features you need to optimize your business operations, but for a successful yard management solution, you need to implement a minimum set of basic features. Let's take a closer look at them.

Gate management

YMS gate management functionality streamlines the process, reducing errors caused by manual intervention. A key optimization step involves replacing stationary computers with handheld mobile devices, which eliminates the time spent walking between the guard shack and truck cabins. YMS can notify managers or dock teams when a truck arrives, helping to reduce labor costs, organize truck movement within the yard, and improve communication — removing the need for phone calls.

An automated gate system is another option that proves efficient. It employs RFID technology to check the verification of the in-and-out equipment by the information sent by the shipper or the carrier. This provides that only authorized vehicles are granted access and prevents unauthorized yard trucks from leaving the premises.

Dock management

The dock management system improves dock-related activities and will increase the facility's overall output efficiency while decreasing the congestion, delays, and expenses for detention. Effective and dynamic scheduling is especially critical for cross-docking models, where time loss must be minimal. Reservation management is the first proposed improvement, which helps solve the problem of making appointments by simply sending hundreds of emails and making lots of phone calls. A system allows carriers and shippers to see available time slots and book or cancel time slots on their own.

Within a YMS, these pre-scheduled appointments integrate with dock scheduling features. The system considers key constraints to create an optimized schedule, assigning trucks to specific dock doors for loading or unloading while allocating the necessary staff and equipment. Prioritization can also be configured to manage high-priority loads first.

If you need a specialized solution for dock management, consider building a cross-docking system. Learn more in our detailed guide.

Asset management

The right yard management system will enhance visibility and streamline asset tracking, automating equipment and cargo monitoring and management. Such methods improved security and accuracy by leveraging Real-Time Location Systems (RTLS).

RFID tags and BLE beacons, attached to assets, store and transmit information to the system when scanned by a reader. BLE beacons can also monitor conditions like temperature, sending alerts for temperature-sensitive items or nearing expiry dates. Unlike barcodes, which require direct line-of-sight, RFID and BLE tags can be read in bulk even when out of view, sharing real-time location data.

By automated asset tracking, YMS enhances safety and security. It reduces the need for manual inspections. Workers no longer need to walk the yard searching for missing assets or conducting inspections, creating a safer and more efficient environment.

Reporting and analytics

YMS allows you to turn raw data into actionable insights into yard. You can get custom supply chain analytics that shows the details of your daily operations at a single readable interface. YMS also helps monitor performance metrics to pinpoint areas that need attention, see optimization opportunities, enhance time management, and make a more informed carrier choice.

Such systems can do different metrics, such as gate, spotters, carries and equipment metrics. Gate metrics include the percentage and number of transactions by transaction type, load type, equipment status, etc. About spotters metrics, they can do such as percentage and number of tasks by type, average time per task, average number of tasks per driver and trends of idle time.

Carrier metrics consume a percentage of on-time, early, or late deliveries, average detention, and others. Finally, equipment metrics include the number of shipments by day of the week, dwell time by equipment type, average delay for late loads, and percentage and number of equipment by load type.

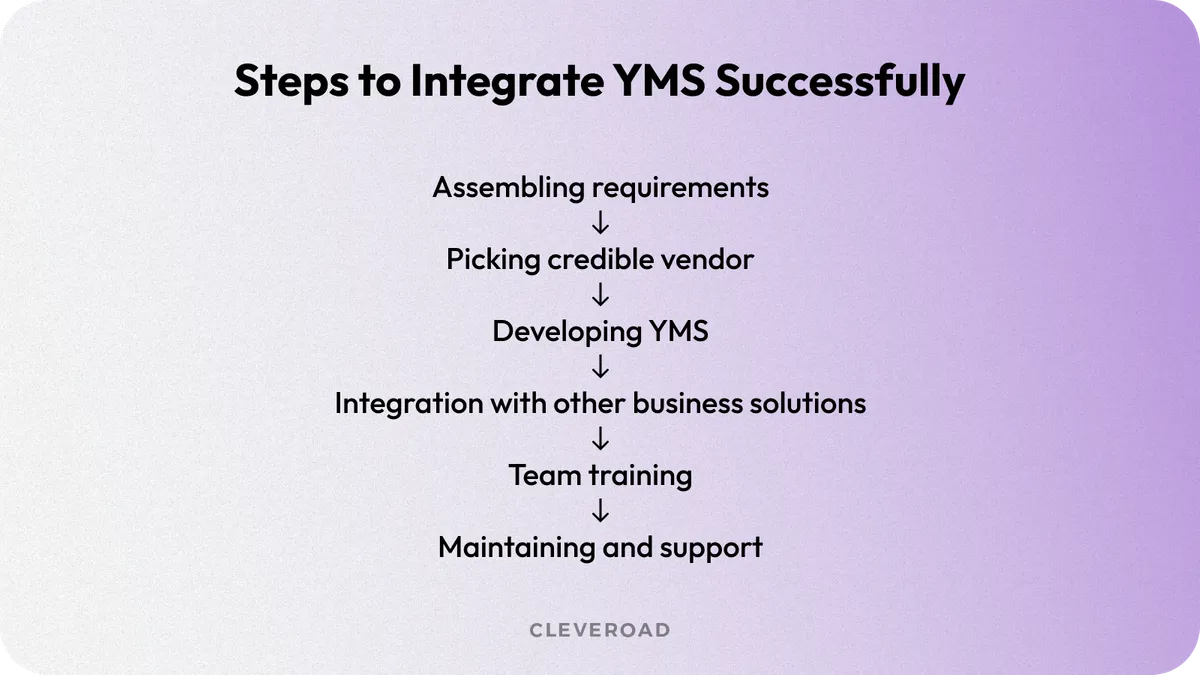

How to Integrate YMS Successfully

After defining the basic functionality to implement, let’s go through the yard management system integration steps.

Steps to Integrate YMS Successfully

Step 1. Picking credible vendor

First, you should select a trustworthy and experienced software vendor who will architect a custom YMS solution for your specific needs. Let’s briefly overview the most popular hiring options to choose from:

In-house team

It is worth mentioning that the in-house team ensures excellent communication levels, great system maintenance, and support capabilities. Yet, this option requires huge contributions from financial resources. This is conditioned by the fact that you have to rent the office for your development team, purchase costly hardware, regularly pay salaries regardless of the scope of work done, etc. As a result, an in-house team is a perfect choice for vast enterprises that require an accessible team of experts and will be able to cover all the essential expenses.

Outsourcing companies

Outsourcing your project is considered the most cost-efficient option. Such companies take over all the product creation responsibilities and have all the proficient software engineers for this goal. You can expand your development capabilities with several experts in specific areas you need or get dedicated development team services, which allows you to get a full team of specialists for yard management system creation. Apart from this, you pay only for the work completed with no extra investments.

The cost varies from country to country; still, the market research indicates that the most adequate price range at a remaining top-notch performance is provided by software development companies from Central Europe, particularly Estonia. They offer high-quality IT services at an hourly rate of $50-$80, which is much lower than $100-$130 in Western Europe or $100-$150 in the US. This tech hub allows receiving a high-quality YMS solution at a reasonable cost. And it’s not the only benefit of this country within the outsourcing- let’s define more reasons to select an Estonian software development partner:

- Reasonable hourly rates allow for building complex software solutions at an affordable cost

- The large pool of talented and proficient experts to choose from

- Free trade to EU and EFTA countries, a 1-hour time zone difference with Western Europe

Find out how to outsource software development and succeed in our comprehensive article

Step 2. Assembling requirements

This stage is also called discovery phase. The discovery phase consumes the collection and analysis of information about your yard. It can be asset location and operations procedures. The second step is scoping your project. According to the collected data, the dedicated team of developers will show you their view on how your YMS can look and what features it will have. A team of developers should set these benchmarks to assess the YMS efficiency and determine how to achieve successful aims.

During this stage, they create a detailed project roadmap for the implementation process. The more in-depth your implementation process will be, the more the final system will meet your expectations and requirements. During the discovery phase, your software development partner will guide you, advise you, and gather additional information.

Step 3. Developing YMS

Developing the yard management system is a complex process that consists of various parts, and they can be different for different vendors. At Cleveroad, we follow an Agile SDLC development methodology, namely the Scrum framework. We create software iteratively, from sprint to sprint — 2-week periods during which a team has to complete a set amount of work.

Each sprint starts with a planning meeting and ends with delivering a stable, working item of a product or functionality to your YMS. Further, QA engineers work on a project until its release and check the functionality developed during each sprint. They test both the backend and frontend and make reports for software developers to fix problems.

Step 4. Integration with other business solutions

In order to streamline your supply chain and logistics operations, you should integrate your YMS with other shipping systems. The choice of integrations depends on the specific needs and objectives of the organization and the complexity of its supply chain execution processes. Here are some related integrations that can enhance the capabilities and efficiency of a yard management system:

- Transport management system (TMS). Integrating with a TMS allows for seamless coordination between yard operations and transportation activities.

- Warehouse Management System (WMS). Integration with a WMS helps manage inventory and warehouse operations.

- Labor Management System (LMS). Integrating with LMS can help optimize labor allocation and improve workforce management.

- Barcode and RFID Systems. Integrating barcode and RFID technologies allows for efficient vehicle and cargo identification.

- IoT Sensors. The IoT sensors can provide specific data on vehicle location, cargo conditions, and environmental factors.

- Electronic Data Interchange (EDI). EDI integration facilitates the exchange of electronic documents and data between trading partners.

- GPS Systems. Real-time tracking of vehicles and assets in the yard through telematics and GPS systems helps improve visibility.

Step 5. Team training

The yard management system is complex software that may serve as an efficient tool when employees know how to make use of it. That is why a detailed guide and practical training for your yard team on the YMS application is a must.

Provide your staff with in-depth instructions and answer the arising questions (if any) concerning the further workflow with this solution. Therefore, the number of issues and errors related to YMS usage will significantly decrease or be entirely eliminated.

Step 6. Maintaining and support

Stable, smooth, and secure operation is a key for every YMS solution. Make sure that you have an advancement strategy for your yard management system. The team of tech experts should regularly conduct support, maintenance, configuration, functionality updating, newer version testing, and other actions to enhance the current YMS solution.

Challenges of Integrating Yard Management System

We’ve prepared a list of yard management challenges you may encounter when implementing the YMS into your logistics business processes.

Regulatory compliance

Meeting regulatory requirements is one of the most widespread challenges you can face while implementing a yard management system.

Let’s explore the critical regulations that govern YMS processes in Europe and understand how compliance is essential not only for legal reasons but also for fostering a safe, sustainable, and efficient supply chain industry ecosystem. Regulations related to Yard Management Systems (YMS) in Europe can vary from one country to another and may also be subject to specific industries or regions.

However, there are some general regulations and standards that may be applicable to YMS processes across the European Union.

| Regulation | Description |

Data privacy | YMS systems often involve collecting and processing data, including information about vehicles, drivers, and shipments |

Import/Export regulations | Customs and import/export regulations play a significant role in international shipments |

Electronic documentation | YMS often relies on electronic records and documentation, so you should ensure compliance with local regulations regarding electronic archiving |

Safety and health standards | Yard management can contribute to safety in warehouse yards. Local regulations and standards related to safety and occupational health |

Transportation regulations | YMS processes are closely related to transportation and logistics. European countries have their own regulations, covering different issues |

Scalability concerns

In an environment of rapid business growth and dynamic technology development, it is critical to build flexibility and scalability into the entire supply chain architecture from the very beginning. Architectures that can adapt to increased workloads and changing business needs ensure not only stability but also growth without the need for dramatic changes to the IT infrastructure.

At Cleveroad, we understand these challenges well and build solutions that scale with your business. As an AWS Select Tier Partner, we develop flexible cloud solutions based on AWS. Our experience enables us to implement architectures that efficiently adapt to changes in data volume, users, or business logic while delivering high performance and reliability.

Data security

In this aspect, the choice of competent and highly qualified developers is extremely important, as a solution such as YMS requires top-notch security. Because the digital yard management system processes and stores sensitive data, you should select an experienced software vendor who is competent in choosing and working with safe and stable data centers according to the location of the entity so that hosted information will remain within the location and comply with its requirements. The protection potency impacts how safely all the automated processes will be completed, so it is important to architect YMS software with solid and powerful security.

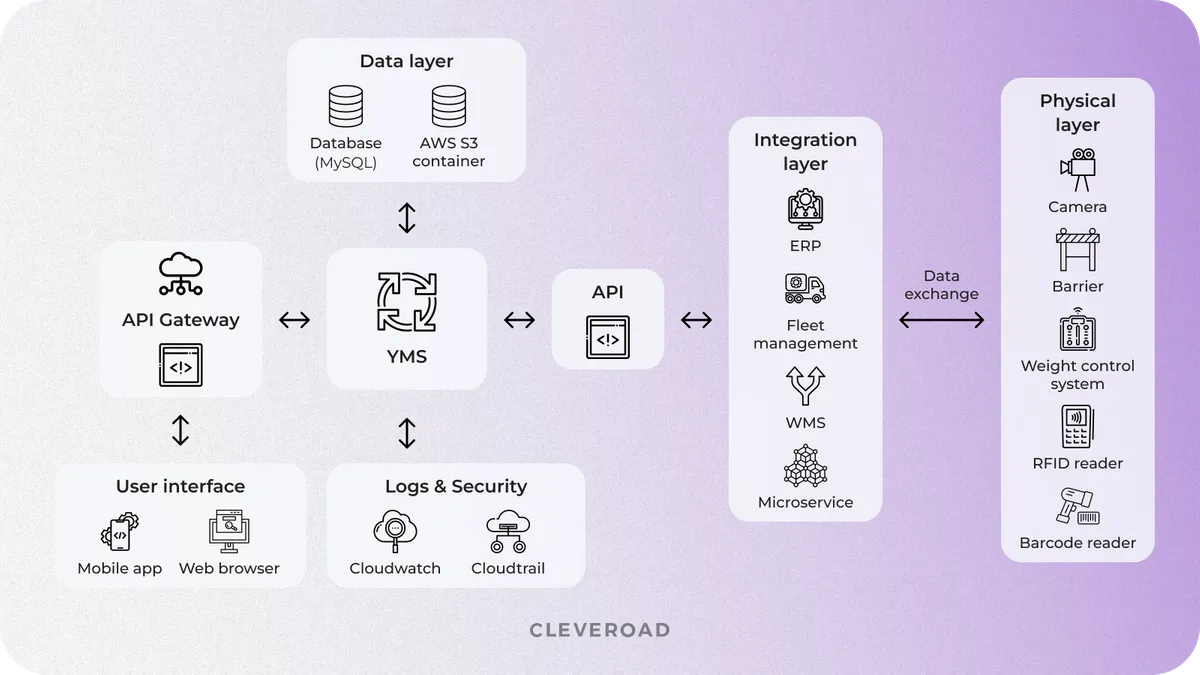

Here's an example of a robust yard management system architecture designed by the Cleveroad team.

Yard management system's solution architecture made by Cleveroad

Cost of Yard Management Systems

After discovering all the essential information about the YMS feature set, let’s consider the approximate development time and price for this logistics system creation. First, let’s consider the basic YMS features as well as their approximate development time and cost.

| Features | Time (h) |

Real-time visibility on yard assets | 180 hours |

Yard driver task optimization | 90 hours |

Dock scheduling | 120 hours |

Gatehouse management | 90 hours |

Integration of external services | 60 hours |

Analytics and reports | 80 hours |

Manual corrections making | 50 hours |

Integration with other management systems (e.g., CRM) | 60 hours |

Access to RBAC by roles | 70 hours |

However, you should keep in mind that the estimate includes only development time without expenditures for other IT specialists. The approximate team composition to create the yard management system is the following:

- Developers (backend/front-end)

- Business analysts

- Project managers

- UI/UX designers

- Solution architects

- QA and DevOps engineers

Thinking out the team composition and the amount of work given above, the rough cost of your YMS will be $70,000-$250,000+. You can book a consultation with our Logistics Business Analysts to know more about the future project estimation details.

How Cleveroad Can Help You with Yard Management System Integration

Cleveroad is an outsourcing IT company from Estonia with a solid 12+ years of experience in providing custom IT-related assistance and logistics software development services.

We help any scale businesses related to the supply chain optimize internal company operations, solve entity challenges successfully, and gain competitive advantages. We are sure that honesty and transparency with our partners and the team are key to building top-quality products. Our clients can choose the most suitable among the three flexible partnership models: Dedicated Development Team, IT Staff Augmentation, and Custom Solution Development.

Working with us, you obtain the following benefits:

- Free Solution Workshop stage to connect your YMS needs with technical implementation.

- High-quality management, proven by an ISO 9001 certificate, to adhere to the quality needs of your software.

- ISO 27001-certified security management based on confirmed policies and processes to ensure data security.

- Experience in working with third-party logistics systems (e.g., Google Maps, LogistaaS, Shopify, etc.) to integrate with your YMS software and streamline your internal flows.

- Hands-on experience in creating YMS logistics software meeting regulatory requirements like GDPR, Regulation (EC) No 561/2006, Regulation (EEC) No 3821/85, Regulation (EC) No 2135/98, Regulation (EU) No 165/2014, etc.

- On-demand IT services for logistics consuming software modernization, custom software development, cloud development, integration with third-party services, etc.

Cleveroad is competent in creating Logistics Management Systems (LMSs), including YMS. We develop products to decrease operational outgoings and optimize supply chains and workflows for warehousing, transportation, cargo delivery, etc. You are welcome to verify our expertise by looking at our portfolio or by reading reviews on our Clutch page.

Build a YMS system with logistics domain experts

Get a robust and resilient YMS system matching your business needs from a tech team with 12+ years of experience in creating software solutions for Logistics domain

Yard management definition is a combination of scheduling, coordinating, and managing operations in a warehouse or distribution center, such as inbound and outbound trucks, personnel, shipments, and others.

A yard management system is multifunctional software allowing you to control and organize all the operations, equipment, vehicles, containers, and resources throughout the entire warehouse, distribution center, or manufacturing facility.

Yard Management includes the scheduling, coordinating, and managing operations in a warehouse or distribution center, such as inbound and outbound trucks, personnel, shipments, and others.

Thinking out the team composition and the amount of work, the rough cost of your YMS will be $70,000-$250,000+. For a more accurate price, please contact us for a consultation.

Yard management consumes optimizing the movement and storage of trucking and trailers in the yard. Warehouse management deals with the efficient handling, storage, and distribution of goods within the warehouse.

Three components of yard management are:

- Clear visibility inside the yard

- Optimizing processes

- Regular communication

Evgeniy Altynpara is a CTO and member of the Forbes Councils’ community of tech professionals. He is an expert in software development and technological entrepreneurship and has 10+years of experience in digital transformation consulting in Healthcare, FinTech, Supply Chain and Logistics

Give us your impressions about this article

Give us your impressions about this article